Functions and advantages

|

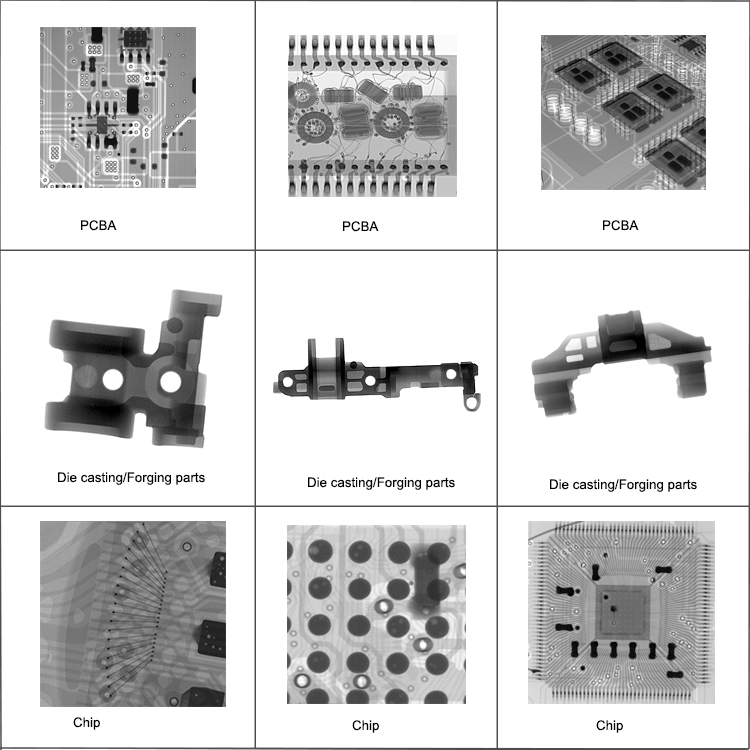

Functions |

CNC program: automatic batch detection of different positions of samples |

|

Array function: automatic batch detection of samples without putting into/out and the same spacing |

|

|

Bubble measurement: one-click measurement of bubble size and void ratio |

|

|

Length and width measurement: measure the length and width of part of the detection area |

|

|

Visual navigation interface: accurate positioning of detection position |

|

|

Simulating color: Better View Inspection Image |

|

|

|

Automatic ON/OFF X-RAY light tube batch inspection of samples |

|

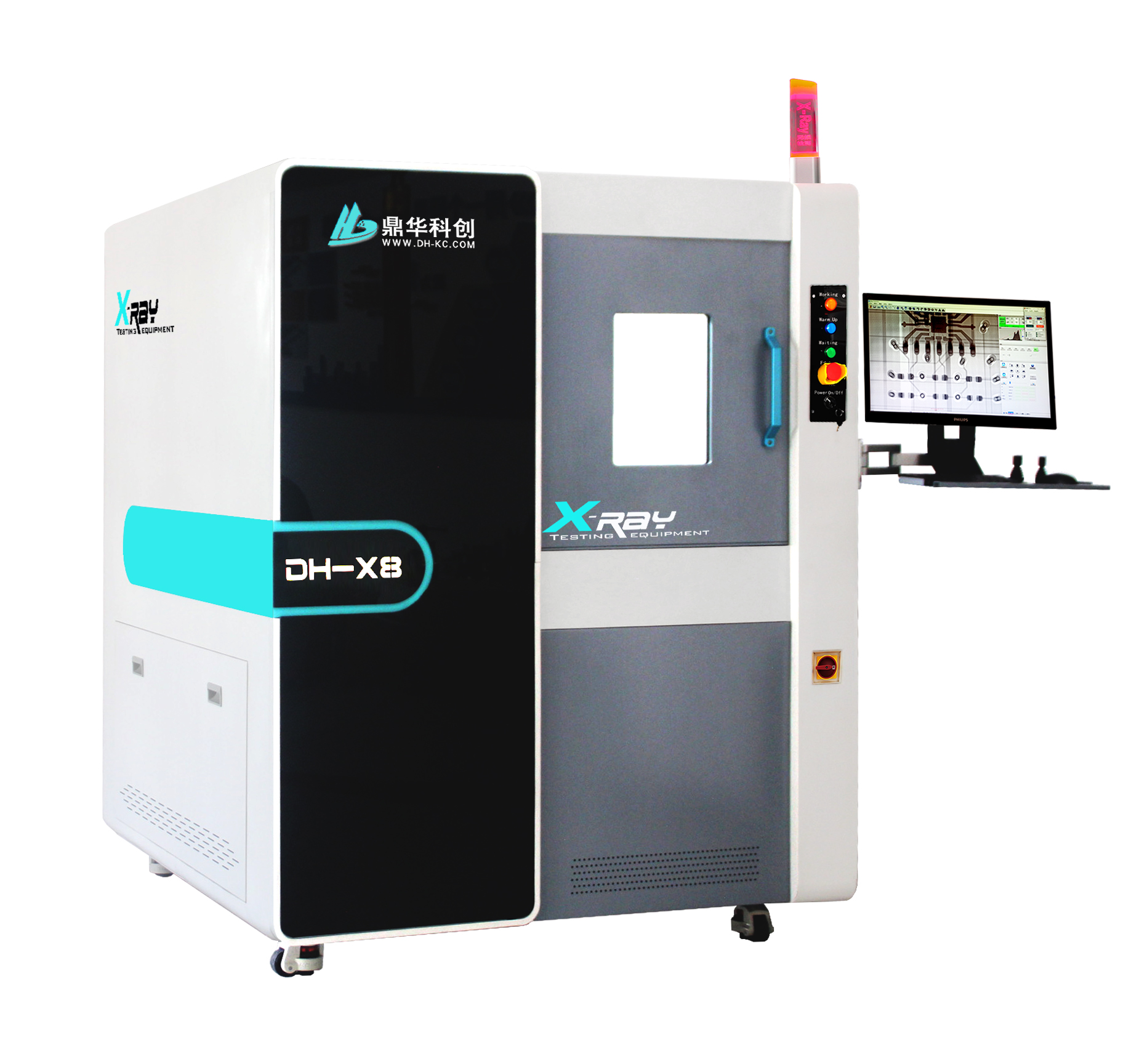

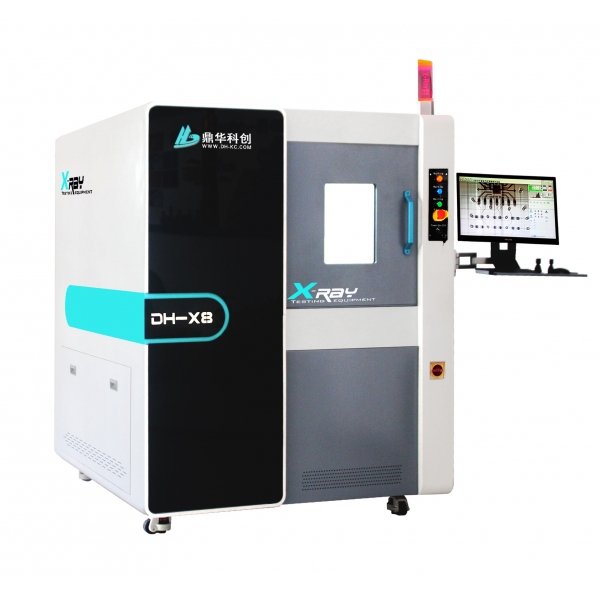

With 90KV Hamamatsu X-RAY light tube, the detection accuracy reaches 5um |

|

|

High resolution digital X-RAY tablet, 1536*1536px image is clearer |

|

|

Geometry magnification 200x, system magnification 1000x |

|

|

510*510mm stage can accommodate a large number of samples of various sizes |

|

|

Semi-automatic NG/OK product inspection |

|

|

Allow 60°~120° oblique observation |

Product acessories

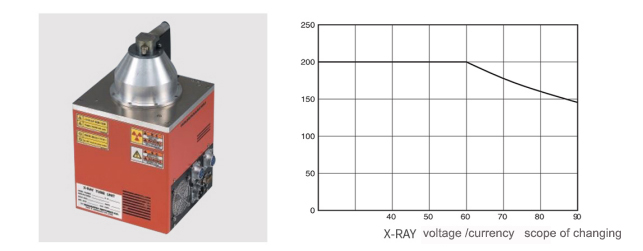

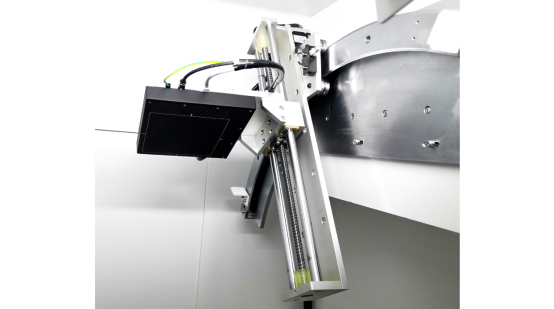

① Microfocus X-ray source

Japan‘s Hamamatsu X-RAY light tube (HAMAMATSU) has a life span of up to 15000H, 90KV light tube

is more commonly used in general-purpose X-RAY equipment, providing it with 5um accuracy.

② Digital HD X-RAY flat panel detection

Defection and application: