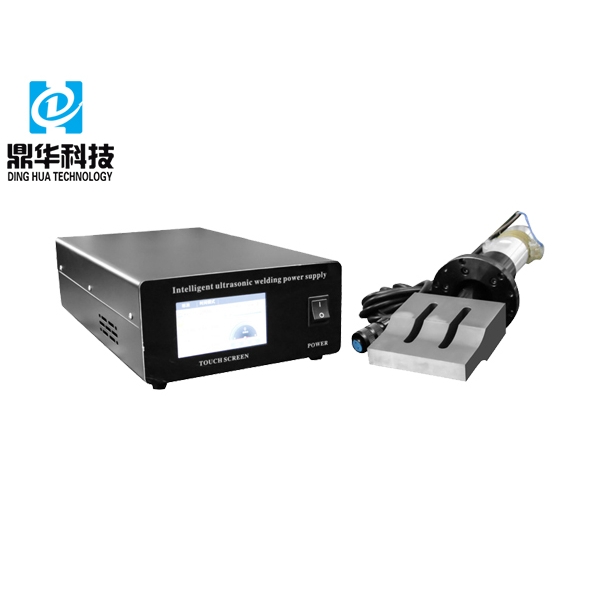

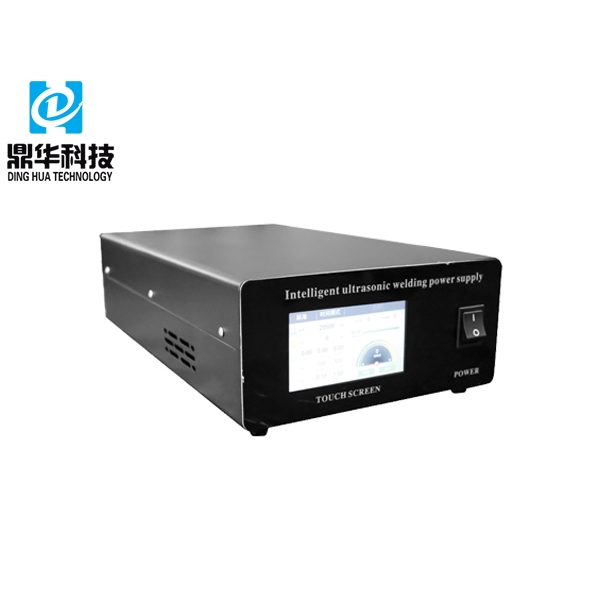

Introduction of 20KHz Ultrasonic Mask Spot Welding Machine

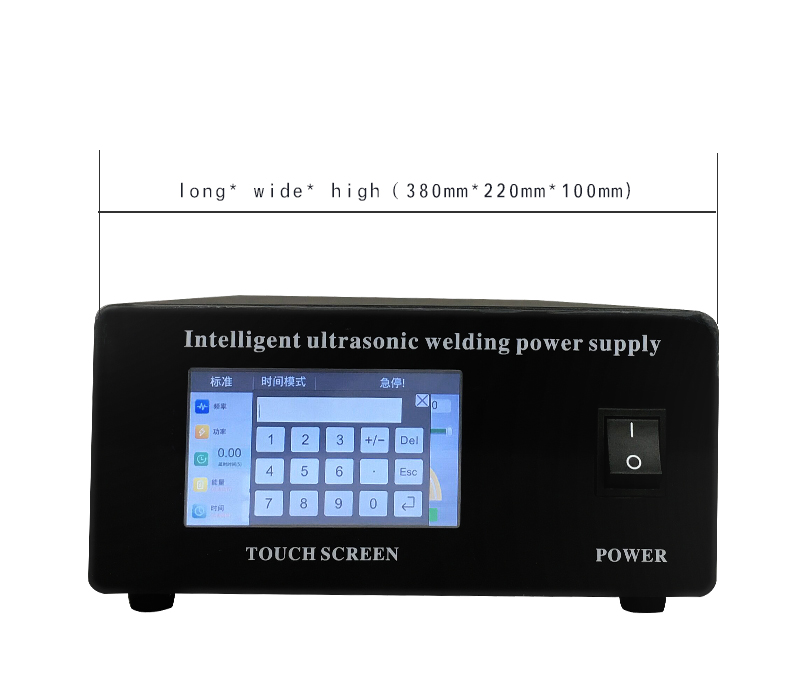

1. Ultrasonic frequency 20KHz; ultrasonic power 2000W; long transmit /short transmit

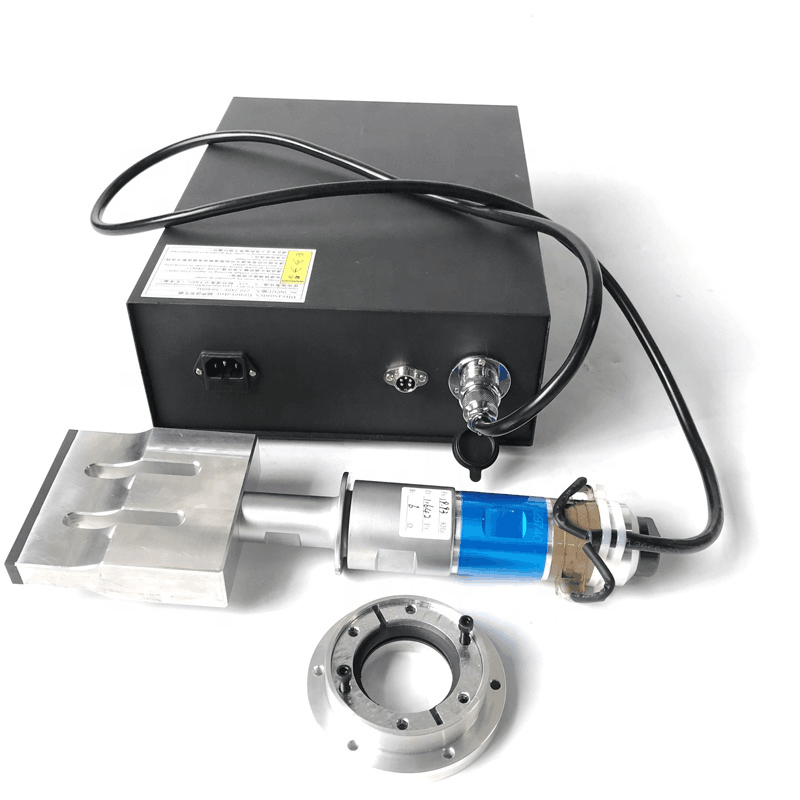

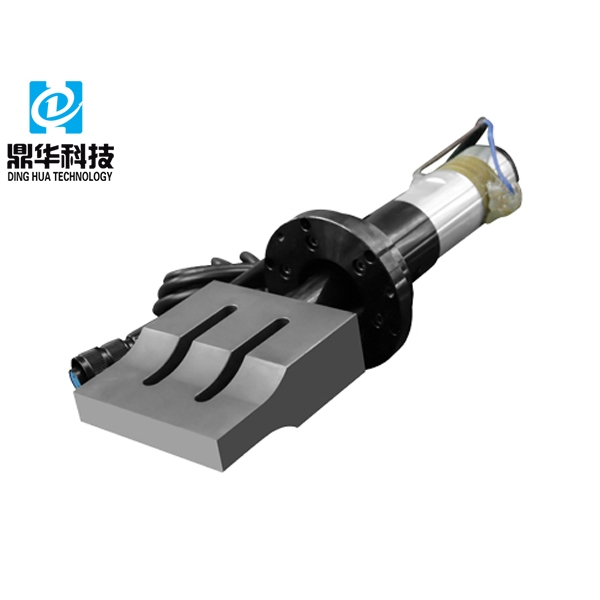

2. 4-piece set of ultrasonic generator, transducer, flange and horn;

3. A full set of 100% debugging and before leaving the factory, the generator, transducer and horn are matched one by one, and the performance is stable

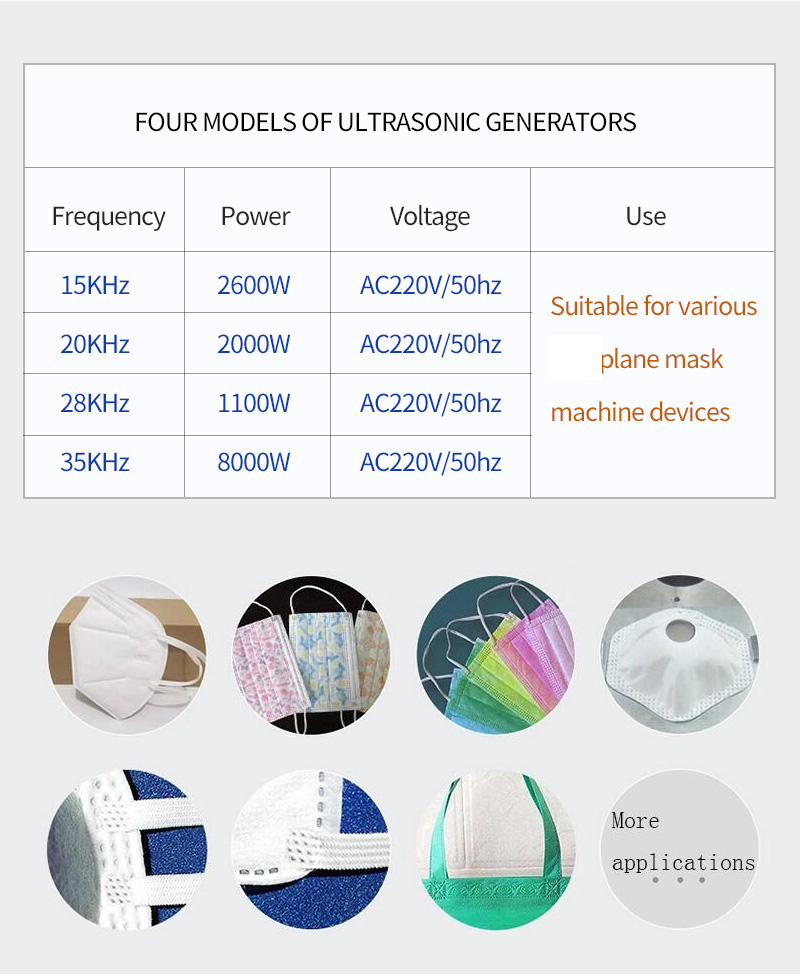

Parameter of ultrasonic generator

Precautions during installation

Do not place the ultrasonic welding machine on a platform affected by vibration. As a last resort, place it upright and fix it on the platform. Otherwise, the life of the ultrasonic welding machine will be shortened.

Do not place the generator in a place where the air contains acid or alkali components. Otherwise, due to corrosion or poor insulation, the life of the ultrasonic welding machine will be shortened and failures will occur.

The ultrasonic welding machine should be placed in a place with a temperature above 15㎝ and a temperature within 0~40℃. There are places with air circulation and air circulation on the front, back and sides of the ultrasonic welding machine. There are semiconductor components inside the ultrasonic welding machine, which are sensitive to temperature. High temperatures can cause malfunctions.

When the power cord of the ultrasonic welding machine is connected, confirm that the power switch is in the "OFF" state. Otherwise, connecting the power cord when the power switch is in the "ON" state will cause a malfunction.

Do not put the remote control wire and other wires together into the power wire, vibration box, and tank connection wire of the ultrasonic welding machine. Otherwise, there is a danger of erroneous operation.

Precautions during use

Do not pour water, alkali or acid liquid into the operation switch of the ultrasonic welding machine. In addition, wet hands cannot directly operate knobs and so on. So as not to cause damage or poor operation. During vibration operation, the interval between "ON" and "OFF" should be turned on for more than 2 seconds.

3. Matters needing attention during maintenance

When maintaining the ultrasonic welding machine, please use neutral detergent. Do not use solvents such as water, alcohol, or lamp oil for cleaning. Otherwise, it may cause the paint of the ultrasonic welding machine to peel off, and some resin products such as knobs are deformed.

.png)

.png)